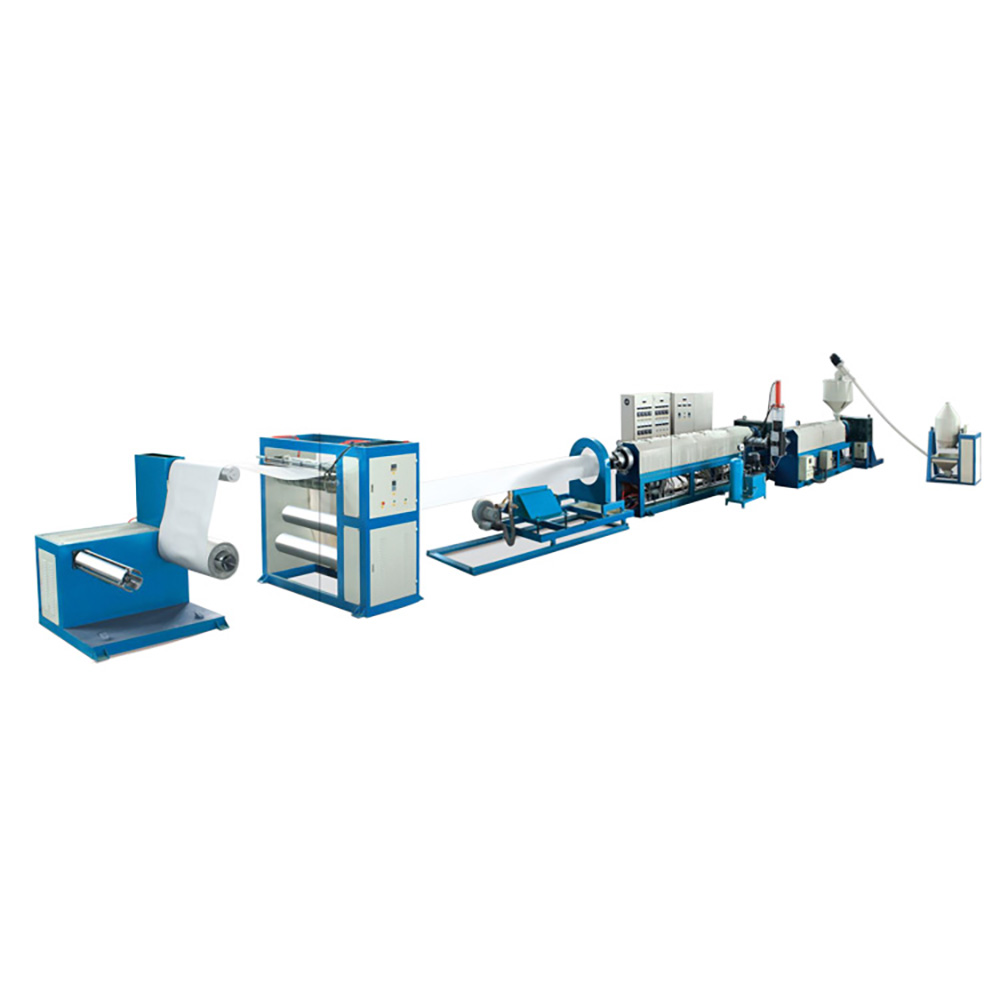

Ps ua npuas ncauj ntawv extrusion tshuab

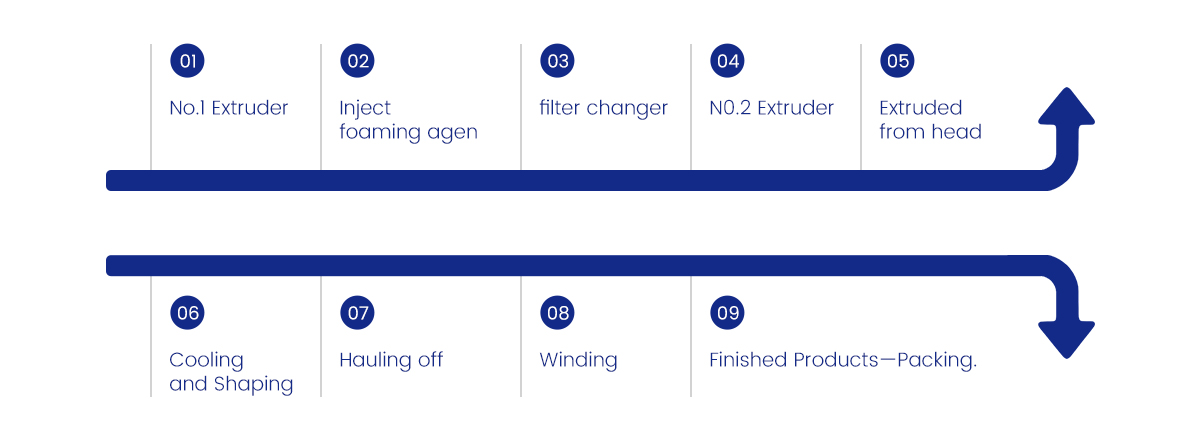

txheej txheem ua haujlwm

tshuab piav qhia

Cov kab ntau lawm adopts dual ntsia hlau ua npuas ncauj ntawv extrusion txheej txheem.Cov khoom siv raw yog dav polystyrene granule.Cov khoom siv no txais kev kub ceev tsis nres hydraulic lim hloov thiab PLC maub los, nws yooj yim rau kev khiav lag luam.Nws muaj kev ua haujlwm ruaj khov, muaj peev xwm loj, siab automation. thiab cov khoom zoo.

Nws yog siv dav hauv kev ntim khoom noj, txiv hmab txiv ntoo, khoom siv hluav taws xob, khoom siv txhua hnub, khoom siv kho vajtse, phaj tshaj tawm, thiab lwm yam xws li lub thawv khoom noj ceev, phaj, t tais, ncuav mog qab zib tais, tais tais thiab lwm yam.

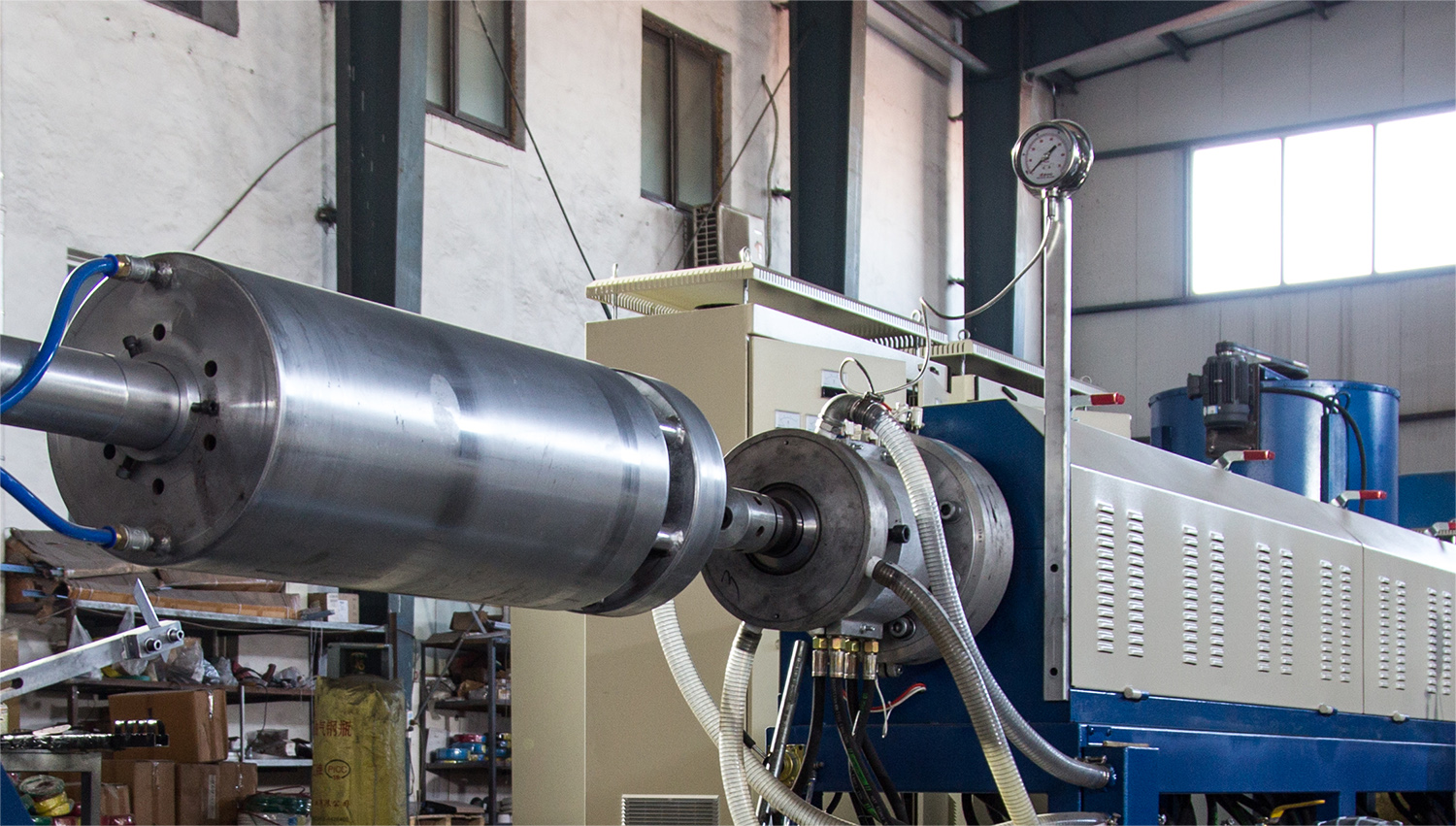

Ntsia hlau

Cov ntsia hlau yog lub plawv ntawm lub extruder .Cov khoom siv yog 38CrMoAlA, uas muaj cov cua kub zoo thiab corrosion kuj, siab qaug zog lub zog, siab kub ua hauj lwm kub mus txog 500 degrees, txheej txheej ntawm cov ntsia hlau yog plated nrog alloy, uas ua rau lub hardness siab dua thiab kev pab lub neej ntev dua.

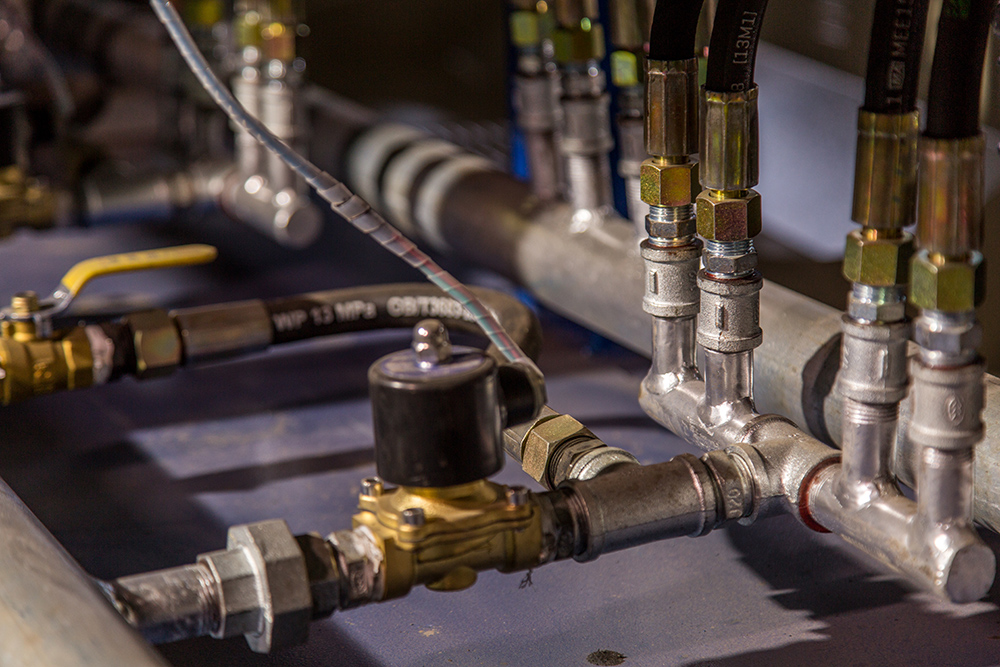

Pub noj system

Cov khoom siv hlau, qhov ntev yog 15 ~ 30 npaug ntawm nws txoj kab uas hla, yog li cov khoom siv raw tuaj yeem ua kom sov thiab ua kom zoo sib xws. xyuas kom muaj txiaj ntsig zoo ntawm cov khoom siv raw.

Txias System

Hollowness dej ncig cua txias thiab shaping nruas Ib txheej (Qhov loj yuav ua raws li cov neeg siv khoom xav tau)