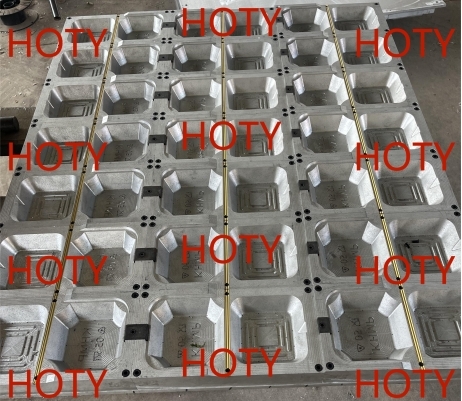

1.PS Zaub Mov Ntim Tshuab Pwm

Cov khoom siv pwm yog ntshiab txhuas, uas yog oxidized thiab polished los ua ib zaj duab xis tiv thaiv ntawm qhov chaw. Cov yeeb yaj kiab tiv thaiv no tuaj yeem tiv thaiv pwm tag nrho, Yog li peb cov pwm muaj kev pab cuam lub neej ntev thiab cov txiaj ntsig zoo molding.

2.EPS Txoj Kev Pwm

Cov khoom siv raw ntawm peb cov pwm yog ob-zero txhuas uas ua tau raws li lub teb chaws tus qauv, tsis muaj impurities, thiab cov pwm muaj qhov zoo toughness, tsis yooj yim tawg, thiab muaj cov thermal conduction thiab txias.

Lub txee lub neej ntawm pwm yog ib xyoos yog tias nws tsis puas los ntawm tib neeg yam.

Lub neej kev pabcuam kuj muaj feem xyuam nrog kev siv cov khoom siv ceev faj. Peb cov pwm muaj lub neej ua haujlwm ntau tshaj kaum xyoo.

3.EPS Foam khob Mould

Cov castings muaj qhov loj me thiab cov duab, zoo rov ua dua, thiab muaj cov yam ntxwv ntawm precision casting.

Qhov saum npoo ntawm EPS pwm yog siab, ua npuas ncauj pwm tsis muaj flash thiab burrs, thiab cov khoom molded muaj siab ncaj ncees.

Post lub sij hawm: Feb-27-2024