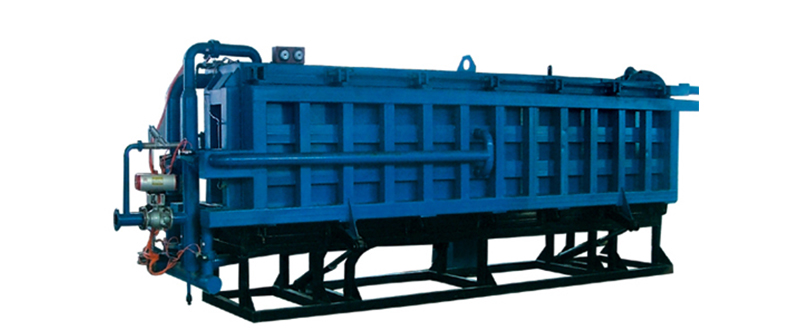

EPS Ua Npuas Ncauj Phaj Sheet Block Moulding Tshuab

txheej txheem ua haujlwm

tshuab piav qhia

EPS thaiv cov kab ntau lawm siv cov txheej txheem EPS kub nkag mus rau qhov zoo tshaj plaws thiab cov qauv zoo ntawm cov kav dej ua ke thiab cov tshuab cua sov tshwj xeeb thiab molding tshuab, kev sib sau ceev ceev, tsawg noj ntawm chav, tsis muaj cov ntsiab lus noo noo, uas ua rau tib lub siab zoo sab hauv thiab sab nrauv thiab txhim khu kev qha tsim ua haujlwm thiab ntau lawm yooj yim thiab txhaum tus nqi qis.transformation blower rau nqus cov ntaub ntawv. nta muaj zog nkag mus, zoo viscosity.

PLC System

Txais PLC lub koos pij tawj kov npo hauv kev tshuaj ntsuam xyuas kom paub txog kev ua haujlwm tsis siv neeg ua haujlwm xws li pwm qhib, pwm kaw, them, cua sov, khaws cia, cua txias, stripping thiab tsis lees paub.

Tshuab Ncej

Txais cov hlau zoo yog welded los ntawm cov yeeb nkab muaj zog thiab cov phaj steel ua kom muaj zog ua kom muaj kev ruaj ntseg ntau dua ntawm lub tshuab; nyob rau hauv lub tshuab thiab ua ke nrog kev kho cua sov kom ntxiv dag zog lub tshuab, tsis hloov nws cov duab. Nws tuaj yeem dais expansibility ntawm cov khoom siv siab.

Cavity

Txais yuav tshwj xeeb aluminium alloy phaj nyob rau hauv tshuab kab noj hniav, siab thermal conductivity, zoo extension thiab ntev lifetime.Tag nrho cov thaiv pwm thav ntawv yog kho los ntawm tshav kub-kho kom tso cov vuam kev nyuaj siab, thiaj li hais tias cov thav duab yuav tsis deformed.